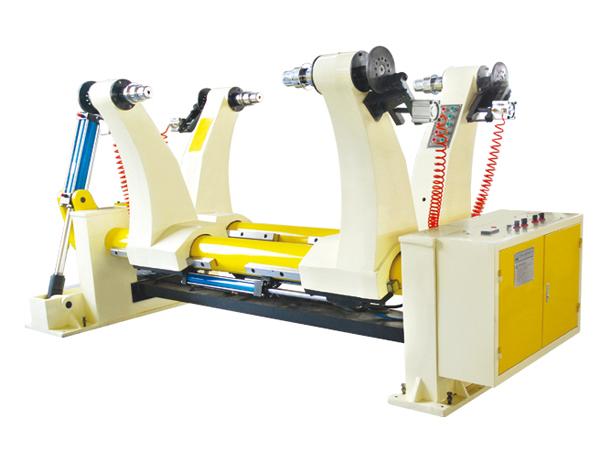

Mill Roll Stand

ZJ-Y Hydraulic shaft less mill roll stand

Technical specifications:

Control type: whole hydraulic type

Working width: Max1600mm, Min800mm

Diameter of paper reel: max ¢1500mm, Min ¢350mm

Single side max loading: 3000kg

Mill roll stand main shaft diameter: ¢215mm

Pneumatic work pressure: 0.6~0.9MPa

Total power: 4.0kw

Working power: 380V, 50Hz

Whole machine dimension: 3650×1600×1680(L×W×H)(when shift swing)

Hydraulic parts:

Working pressure: 12~16 MPa

Hydraulic working area (swing): ¢100mm×460mm

Hydraulic diameter (clamp): ¢63mm×720mm

Hydraulic station power: 4.0kw, continue work

Hydraulic station: 220V, 50Hz

Structure characteristics:

Symmetrical design that can be loaded without stopping the machine.

Hydraulic control. Lifting and lowering, open-close and right-right adjustments of arms are operated by hydraulic system

Pneumatic control for web tension

Tapered center design

Main bought-in parts, raw materials and origin:

1. Main shaft of mill roll stand: Qualified thick seamless steel pipes, origin: Chengdu

2. Wall plate two sides: steel 20# origin: Hebei

3. Clamp arms: HT250 casting, origin: Hebei

4. Main beam connecting channel steel: 280mm origin: Angang

5. Bearing: from Ha, Wa, Luo

6. Electric system: Chint China.

7. Pneumatic parts: Airtac and Zaozhuang, Origin: Taiwan and Shandong

8. Hydraulic parts: Beiye group(Huade) Origin: Taiwan and Shandong

Electrical Mill Roll Stand

Characteristics

1. The stand's structure is symmetrical and can load two rolls of paper at the same time.

2. Paper rolls can be changed without stopping the machine.

3. Effective working width: 1400, 1600, 1800, 2000mm

4. Max. raw paper dia: Ø1600mm

5. Min. raw paper size: Ø400mm×900mm

6. Max. load of single arm: 1500kg.

7. The length of the steel rail is 4500mm.

8. Use disk brake, have handle and electrical models. (can choose.)

9. The clip head is made from cast-iron and also comes in a double expanded optional model.

10. Electrical elements are centrally controlled, improving efficiency

Technological parameters:

1. Paper roll frame working model: Mechanical electrical operation.

2. Paper roll length scope: Max.: 1600mm Min.:900mm

3. Paper roll diameter scope: Max.: 1400mm Min.:400mm

4. Single side max. load: 1500kg.

5. Motor power: (all are planet cycloid motor)

1) Clip motor: 0.75KW 4units 380V 50HZ

2) Up and down motor: 2.2KW 1unit 380V 50HZ

Paper roll up-dolly and rail

1) Stable rolling with a directional leading wheel on the dolly.

2) Each roll stand has two paper roll sending rails, it can load the rolls on both sides simultaneously.