2 ply Corrugated Board Production Line

Our 2 ply corrugated board production line is also referred to as a single facer line. The single facer line is composed of a paper roll stand, a single facer unit and a paper cutting unit.

The board production line creates and cuts single face corrugated paper without the need for drying. This unit is highly automated and easy to use and is found in a variety of cardboard factories.

| Working Width | 1400mm | 1600mm | 1800mm | 2000mm |

| Heating method | Electrical heating/ Oil heating / Steam heating | |||

| Design speed | 100-120 m/min | |||

| Economical speed | 80-100 m/min | |||

| Compress-air pressure | 0.4-0.9MPa | |||

| Flute type | Standard flute | UV Flute | ||

| Single facer machine | Standard spec. | A,B,C,E,F | ||

| For other type and model, we can produce as customer's requirement. |

||||

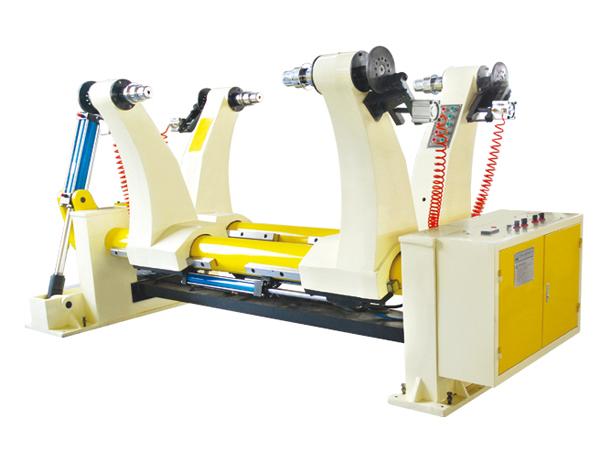

Control type: whole hydraulic type

Working width: Max1600mm, Min800mm

Diameter of paper reel: max ¢1500mm, Min ¢350mm

Single side max loading: 3000kg

Speed : 30-35m/min

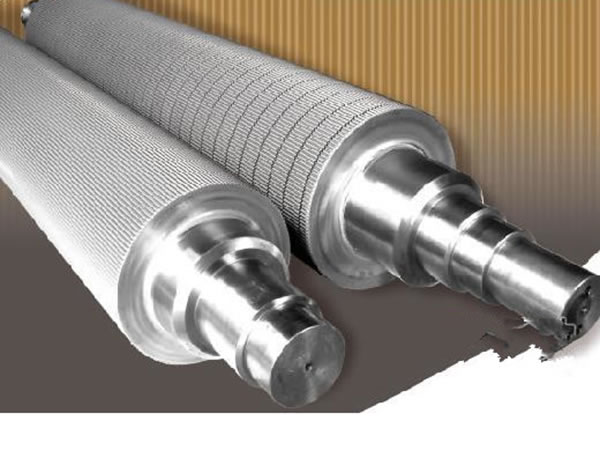

Corrugation roller (242 mm)

Roller material: 45# steel

The corrugated roller, pressure roller, and glue roller by pneumatic system.

Electric heating style .(can choose steam or oil heating)

Manually adjust the glue width divider to match the paper width

Glue part auto supply glue circularly.

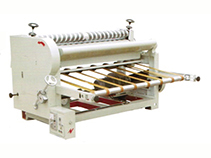

The single facer is the primary piece of equipment used in the production of corrugated paperboard. The fingerless single facer features a vacuum suction component that greatly increases production precision.

The light duty rotary sheeter is a cutting machine that is used to cut cylinder paper or single paperboard sections into quadrangles or as needed. The machine is convenient and easily adjusted.

Our heavy duty rotary sheeter performs precise cutting operations for large quantities of paperboard. The speed and reliability of the cutting machine is unparalleled and it is an excellent economic choice for your cardboard production line.

Our computerized rotary sheeter is a cylinder cutting machine that is designed for the cutting of paper tubes or single paperboard. The rotary sheeter uses a touch screen system that is easily operated to initiate automatic operation. The frequency controlled system is highly reliable and performs precise and consistent cuts.

The hardness of corrugated rolls is directly related to the lifetime durability of the rolls themselves. Low hardness will speed up undesirable wear. Our rolls feature a layer of 4-5mm tungsten carbide. This material requires less repairs and greatly extends the life of the cardboard machinery.