- Single Facer (Fingerless Type)

- Single Facer (for Wave Flute)

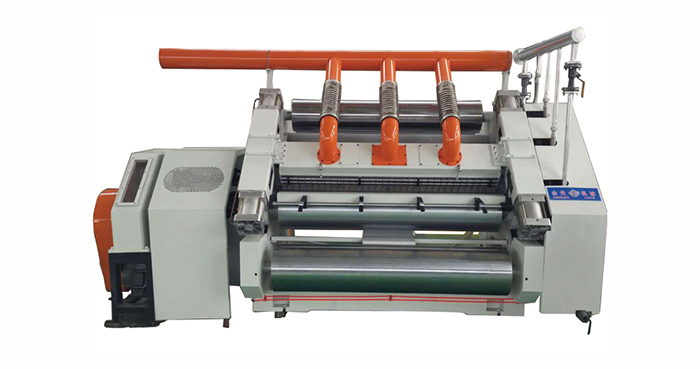

SF-280 Corrugated Fingerless Type Single Facer

Introduction:

The single facer is the primary piece of equipment used in the production of corrugated paperboard. The fingerless single facer features a vacuum suction component that greatly increases production precision.

Characteristics:

1. Cover vacuum suction.

2. The corrugating roll is made of high quality alloy steel 48CrMo.

3. No gear transmission.

4. Glue roll is lifted and lowered pneumatically.

5. Independent glue cleaning device and electric glue-separating board to control the width of glue application.

6. Manually regulate or electrically regulate the display device.

7. Lubricated by high temperature grease.

8. The surface of all dancing rolls and preheating rolls is grinded and chrome-plated.

9. Pressure roll is medium- frequency quenched and chrome-plated.

10. Width 1400mm~2000mm.

11. Working pressure is 1.1MPa.

12. Corrugated roller diameter:270mm

1. A vacuum system is placed within the outer housing, comprising a high-pressure blower and noise reduction silencer. Pneumatic and electrical controls come in an electrical enclosure, which is 1.5 meters from the corrugating machine. A protective cover is also available for maximum operator protection.

2. The base and side frames are constructed from heavy-gauge cast iron in 130mm thickness. Gearbox is built separately from the machine frame and comes with a universal joint.

3. Corrugating rolls are made from 48CrMo alloy steel that receives laser hardening and grinding processes to achieve HRC60 hardness. Roll diameter: 280mm. Bearings are included. Pressure roller withstands high temperature.

4. Pressure roller diameter: 324mm. Receives grinding, tempering and chrome plating processes. Pneumatic cylinder is used to control its up and down movement. Steel grade: 45#, medium carbon content.

5. Pneumatic control supply or reback the glue, coating glue roller diameter 215mm ,surface after grinding ,carved 25 line steel pit anilox , then chrome plated , even glue roller after grinding then chrome plated .

6. Corrugated roller and pressure roller materials are supplied by zhongyuan Tegang. Corrugated roller: 0.15mm, in medium height; pressure roller single side: 0.075mm in medium height.

Pressure cylinder diameter: 160mm

Pre-heater diameter 320mm, made of seamless steel, connected by steel braided hoses.

7. Work speed: 60-80m/min

8. Flute types: A, B, C, E, F

| Working Width | 1600mm | 1800mm | 2000mm | 2200mm | |||

| Heating method | Oil heating / Steam heating/electrical heating | ||||||

| Design speed | 70 m /min | ||||||

| Economical speed | 30-50 m/min | ||||||

| Compress-air pressure | 0.4-0.9MPa | ||||||

| Flute type | Standard flute | UV E Flute | |||||

| Standard spec. | A,B,C,E,F | ||||||

| For other types and models, we can produce custom orders | |||||||

| Corrugated roll diameter (mm) | 2 80 | ||||||

| Wall Thickness (mm) | 130 | ||||||

| Type | Vacuum Absorb | ||||||

| Roller material | 48CrMo alloy, Heat treated | ||||||

| Machine Size (mm) | 3300*1300*1700 | 3550*1300*1700 | 3800*1300*1700 | 4050*1300*1700 | |||

KSJ Double single-face corrugated line Type D

Single face corrugated paper required

This model of single facer is designed for the production of wave flute corrugation for special types of paperboard. The machine uses vacuum absorption and steam heating modes. The automatic function of the equipment leads to less wasted resources and greatly improved efficiency.

Technical Parameters

Paper width: 900mm

Mechanical velocity: 60m/min

Heating Type: steam

Parameters of Main Parts

Upper corrugated roller: Φ280mm

Lower corrugated roller: Φ280mm

Pressure Roller: Φ280mm 45# seamless steel pipe, quenched

Glue Roller: Φ240mm 45# seamless steel pipe, surface treated with special mesh nicking and chrome-plating

Glue Scraping Roller: Φ120mm 20# seamless steel pipe

Pre-heating Roller: Φ294mm 20G Jigang steel

Wall thickness: 18mm